Steel Rule Die Making Services

Custom Steel Rule Dies for Precision Cutting

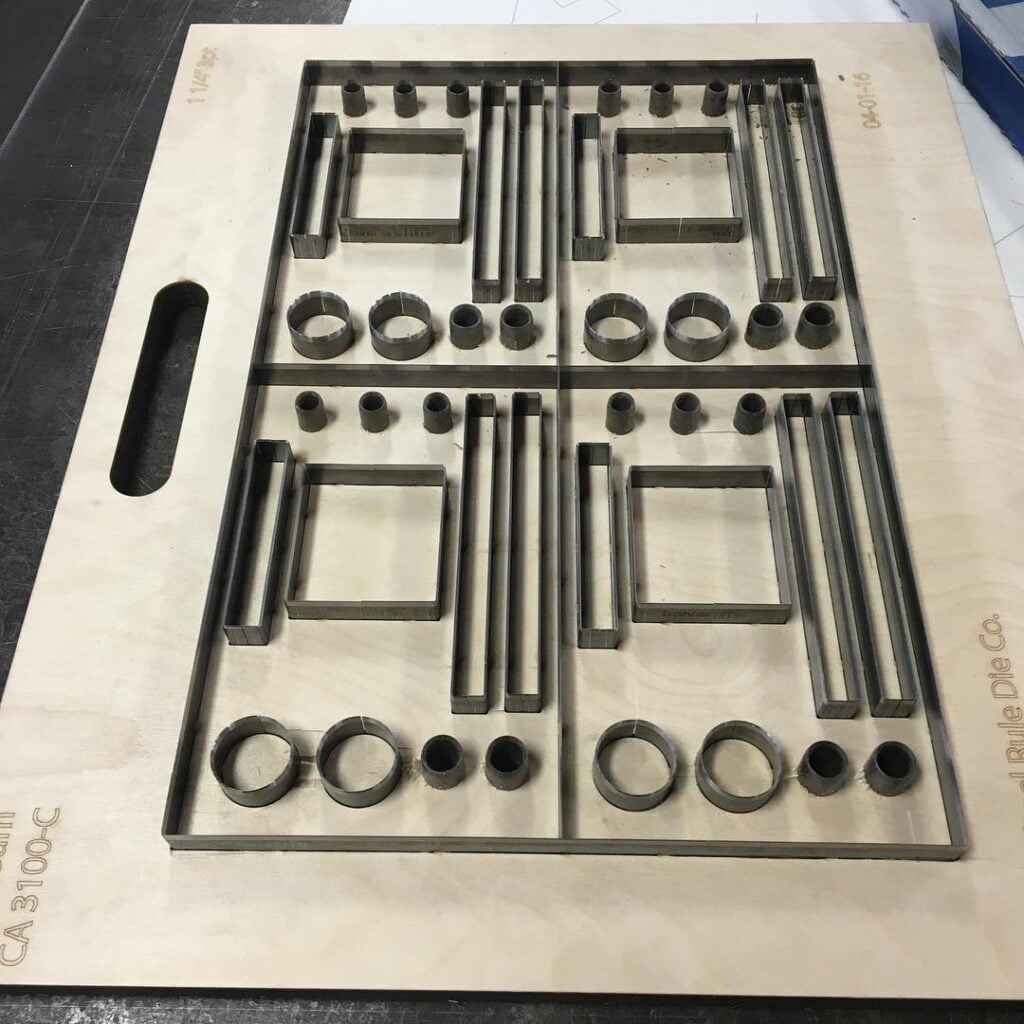

At Product Identification Company (PIC), we design and manufacture custom steel rule dies in-house to ensure precision, fast turnaround, and cost savings for our customers. Our laser-burned dies and advanced bending technology allow us to cut a wide range of materials, including plastics, foams, paper, corrugated board, and more. By keeping die-making under our roof, we eliminate outsourcing delays, giving you consistent quality and quicker lead times for your projects.

Steel Rule Die Making Capabilities

-

Automatic Rule Bending: Our BendPro 320D ensures precise bending, notching, and assembly of steel rule dies.

-

Laser Burned Die Boards: For maximum accuracy and tight tolerances.

-

Die Sizes: Custom dies for both small-format and large format die cutting projects.

-

Variety of Blades: Cutting, scoring, perforating, and serrated blades depending on application.

-

Fast Turnaround: Because we make dies in-house, we eliminate outsourcing delays and improve lead times.

Materials Supported with Steel Rule Dies

Our dies are built to cut a wide range of materials, including:

-

Plastics: PVC, polystyrene, expanded PVC (Sintra), PETG, polycarbonate (Lexan), acrylic.

-

Metals & Foils: Aluminum foil, thin-gauge metals.

-

Paper & Board: Chipboard, corrugated, cardstock, and folding carton board.

-

Films & Laminates: Polyester (Mylar), BOPP, pressure-sensitive films.

-

Foams & Rubber: Gasket materials, foam sheets.

-

Wood & Specialty Materials (with heated platen presses).

What Is Steel Rule Die Making?

Steel rule die making is the process of creating cutting dies used to stamp, cut, crease, or perforate materials. These dies are essential for die-cutting processes and allow us to cut a variety of materials into consistent, repeatable shapes. At PIC, we produce custom dies for both short runs and high-volume production, serving industries from defense and aerospace to packaging, retail, and industrial manufacturing.

Applications of Custom Steel Rule Dies

Our die-making services support both short-run prototyping and high-volume production. Common applications include:

-

Gaskets and Industrial Parts – Precision-cut seals and liners.

-

Packaging & Inserts – Custom shapes for corrugated and foam packaging.

-

POP Displays & Signage – Die-cut retail and promotional components.

-

Labels, Overlays & Decals – Cleanly cut shapes for branding and industrial identification.

Advantages of In-House Die Making

PIC’s in-house die-making capabilities give your business a clear advantage:

-

Faster Lead Times – No waiting for outsourced dies.

-

Lower Costs – Eliminates third-party die-making expenses.

-

Tighter Tolerances – Precision-built dies designed for our presses and cutting systems.

-

Flexibility – Easily accommodate both simple and complex part geometries.

Products Made with Steel Rule Dies

Steel rule dies are at the core of many of PIC’s services. With our die-making capabilities, we produce:

-

Custom nameplates and overlays

-

Labels and decals (die-cut from roll or sheet stock)

-

Gaskets and industrial components

-

Folding cartons and packaging components

-

POP displays and promotional signage

-

Foam inserts and protective packaging

Advanced Die Making Equipment

Our in-house equipment ensures every die is built with accuracy, durability, and repeatability:

-

BendPro 320D Automatic Steel Rule Bending Machine – Creates complex die profiles with speed and precision.

-

Laser-Burned Dies – Provides sharp, clean edges for exact material cutting.

-

Heated Platen Die-Cutting Presses – Ideal for plastics and thicker materials requiring precision heat-assisted cutting.

Contact Us for Your Custom Steel Rule Dies

Looking for custom steel rule dies for plastics, foams, paper, corrugated, or gaskets?

PIC’s in-house die-making team is ready to deliver precision-built dies for your next project.

📩 Contact us today at info@alpack-pic.com or call to discuss your requirements.

Let's Connect & Get To Work

Whether you’re ready to start a project or simply need guidance on where to begin, we’re here to help. Our commitment to your satisfaction drives us to offer comprehensive support tailored to your needs.

Feel free to use the contact information provided on this page, or take advantage of the contact form below to get in touch. We value your interest and look forward to connecting with you soon!