Finishing Services

Complete Finishing Solutions for Printed & Cut Products

At Product Identification Company (PIC), we know that the finishing stage is just as important as printing or cutting. Our finishing services ensure that your products are durable, functional, and presentation-ready. With capabilities including mounting, laminating, heat bending, hot stamping, riveting, assembly, and more, we deliver high-quality finished components for industries such as defense, retail, medical, packaging, and manufacturing.

Materials We Commonly Work With

Our finishing capabilities support a wide range of materials including:

-

Acrylic & PETG (with adhesive mounting or bending)

-

Foam board & gator board

-

Rigid vinyl, Sintra, and polystyrene

-

Paper, chipboard, corrugated, and litho board (min. 10 pt litho mounted to styrene or Sintra)

-

Flexible vinyl, polyester films & polycarbonate films

-

Metal foils and nameplate materials

Mounting & Adhesive Applications

Our finishing team provides full mounting services, including:

-

Second-surface mounting of optically clear adhesives to acrylic and PETG (only wax/silicone-free coatings accepted).

-

Mounting paper to board, foam to board, and vinyl to rigid substrates like Sintra, styrene, and corrugated plastic.

-

Automatic Kleenstick application and foam tape application for displays, labels, and packaging components.

These processes allow us to produce finished signage, packaging inserts, overlays, and structural components with professional, durable adhesive finishes.

Laminating & Protective Finishes

With film laminating up to 60” wide and roll-to-roll / roll-to-sheet options, we protect and enhance your products with laminates that resist scratches, chemicals, and UV exposure. Our laminating capabilities are ideal for:

-

POP displays and retail graphics

-

Instructional placards and overlays

-

Durable labels and packaging components

👉 Related Service: Laminating Services

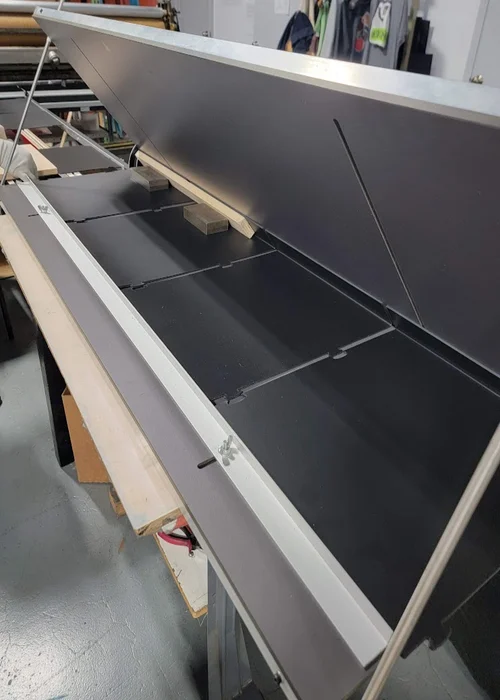

Heat Bending & Acrylic Fabrication

PIC’s finishing shop features specialized equipment for heat bending plastics, enabling us to produce folded signs, POP displays, and custom acrylic parts. Our acrylic fabrication services extend to cutting, shaping, and polishing of acrylic and plastics, making us a complete resource for finished components.

👉 Related Service: Laser Cutting Services

Heated Die-Cutting & Clicker Presses

With multiple heated die-cutting presses (up to 55” x 78” in one pass and 60” x 90” in two hits), PIC specializes in cutting thick plastics and unusual substrates that require heat for clean, accurate edges. Our clicker presses allow us to cut smaller parts from materials such as foam, rubber gaskets, adhesives, and laminates. This flexibility makes us the go-to for both industrial die-cut parts and retail display components. The heated press also enables us to provide precision kiss cut label sheets.

👉 Related Service: Large Format Die Cutting

Hot Stamping, Riveting & Eyeletting

We provide hot stamping for decorative and functional finishes on paper, plastic and customer supplied parts. Our team also handles riveting and eyeletting for structural assembly, ensuring that parts, folders, or displays are securely finished. This service is often combined with our die-cutting and mounting operations to deliver fully assembled and production-ready parts.

Grommeting, Eyeletting & Gluing

For projects requiring assembly, PIC provides:

-

Grommeting and eyeletting for structural reinforcement in folders, binders, or displays.

-

Gluing of easels, folders, and pockets to complete retail and packaging components.

-

Hot stamping services for decorative and branding finishes.

These mechanical and adhesive finishing services allow us to deliver structurally sound, customer-ready parts.

Assembly, Kitting, Packouts & Drop Shipping

PIC offers full-service assembly and fulfillment for clients who want a turnkey solution. Services include:

-

Assembly of display components

-

Packouts for retail or defense distribution

-

Drop shipping directly to end-users

This eliminates the need for customers to use multiple vendors, saving time and cost while ensuring consistency.

Ready to complete your project with professional finishing services?

PIC offers mounting, laminating, heat bending, kitting, and more — all in-house for faster turnaround and lower costs.

📧 Contact us today at info@alpack-pic.com to get started.

Let's Connect & Get To Work

Whether you’re ready to start a project or simply need guidance on where to begin, we’re here to help. Our commitment to your satisfaction drives us to offer comprehensive support tailored to your needs.

Feel free to use the contact information provided on this page, or take advantage of the contact form below to get in touch. We value your interest and look forward to connecting with you soon!